Holtek offers a wide variety of MCUs, for 8bit and 32bit. They focus on application-based MCUs, so if there is a specific product-group, Holtek might have the perfect fitting MCU for this product. Today’s closer look will focus on heating up a coil – for example used in cooking plates.

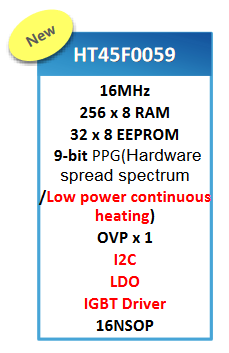

With a focus in the induction cooker application area, Holtek  announces the release of its new low power continuous heating induction cooker Flash MCU, the HT45F0059. This low power device ensures that induction cookers can generate a uniform and efficient heating source.

announces the release of its new low power continuous heating induction cooker Flash MCU, the HT45F0059. This low power device ensures that induction cookers can generate a uniform and efficient heating source.

It not only features the typical memories etc., but also a 9-bit programmable pulse generator and an IGBT driver to heat up the coil!

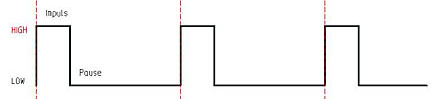

In general: For warming up any liquid, like your typical water heater, you will heat up a coil for it. This process typically requires short bursts of strong current-flow and longer periods of no current/heat product at all, like a PWM signal:

But with Holteks “low power continuous heating” principle, the current will flow permanently through the coil. No burst – just continuous heat. Below you can see a comparison between both types of heating.

General solution:

Intermittent heating, the firepower is turned on and off suddenly

⇒ poor heating efficiency

HT45F0059 solution:

Continuous heating, average and uninterrupted firepower

⇒ improved heating efficiency

Not only efficient, but also lower the EMI!

The device includes an internal hardware frequency jittering function, which can effectively reduce the IGBT VCE back voltage and consequently reduce any generated electromagnetic interference – EMI. This will also reduce the cost of any required anti-electromagnetic interference components usually required when the induction cooker operates in a high-power condition. The integrated IGBT drive circuit can directly drive the IGBT, thus further reducing the number of required external components and reducing the PCB layout complexity.

Here an application example for an induction heating plate with controls:

We also want to mention, that we can provide the fitting IGBT for the inductive heating process!

The device has a range of hardware protection mechanisms including surge protection, IGBT over-voltage protection and valley voltage detection etc. The device is delivered in a 16-pin NSOP package type.

To summarize the advantages:

Stay tuned for the next “closer look @ Holtek”!